The catalyst for waste oil is mainly used for the catalytic cracking of waste oil. The catalyst can further catalyze the oil which can not be processed after the waste oil is gradually distilled, so as to extract more and better diesel and gasoline from the waste oil. It include waste engine oil catalyst, waste plastic oil, waste tire oil.

As we know the difference between the engine oil and diesel fuel is the molecular structure and molecular weight. The molecular weight of the engine oil is large, while the molecular weight of diesel and gasoline is small. Based on this, put the waste engine oil into the refinery equipment, under a certain temperature (330±20 °C) with our catalyst, the oil molecules produce complex chemical reactions such as ring opening, chain scission and condensation, which generate diesel, gasoline and a small amount. Combustible gas and residual oil. Also our catalyst is high selectivity to the diesel, high cetane number of the diesel. The oil refinery with catalyst no bad smell, also the color is much bright, close to water or light yellow color. And the oil quality close to the national standard. Also, the catalyst can reuse 2-3 times after recycled. 1 ton catalyst can refinery 500-1000 tons oil

Item number: KSC-4A, KSC-4B

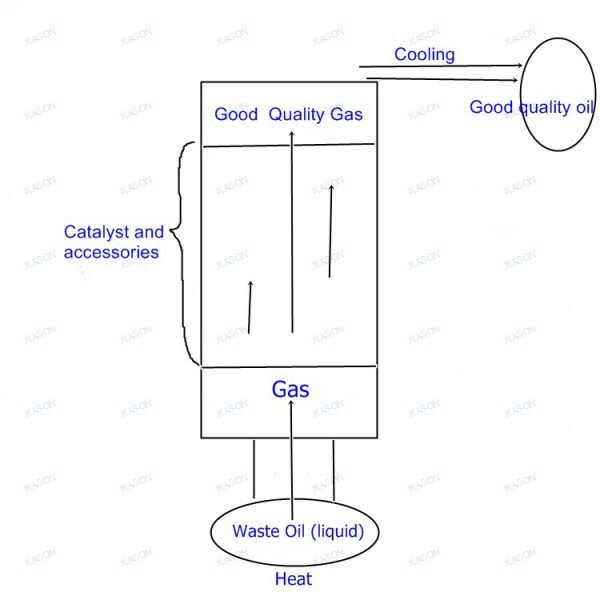

Above is the picture about how the catalyst refinery the waste engine oil to diesel oil

| Item | 4A | 4B | ||

| Standard | Test Result | Standard | Test Result | |

| Size mm | Φ2.5*2-10 | Φ2.5*4 | Φ3*2-10 | Φ3*6 |

| Pore Volume ml/g | ≧0.3 | 0.45 | ≧0.28 | 0.39 |

| Specific Surface Area m2/g | ≧235 | 260 | ≧250 | 278 |

| Crushing Strength N/cm | ≧125 | 130 | ≧130 | 142 |

| Bulk Density kg/l | ≥0.7 | 0.72 | ≧0.7 | 0.77 |

| Abrasion wt% | ≦1 | 0.3 | ≦1 | 0.6 |

Catalyst packing should be with bag or barrel packing.

Bag packing with 25kg/bag, barrel packing with 40kg/barrel.

Bag packing with 15-18 tons in 1*20GP, barrel packing with 14-15 tons in 1*20GP.

Contact Form