Welcome to Dongying Kason Import&Export Co., Ltd

If kerosene contains aromatic components?

2024-10-29

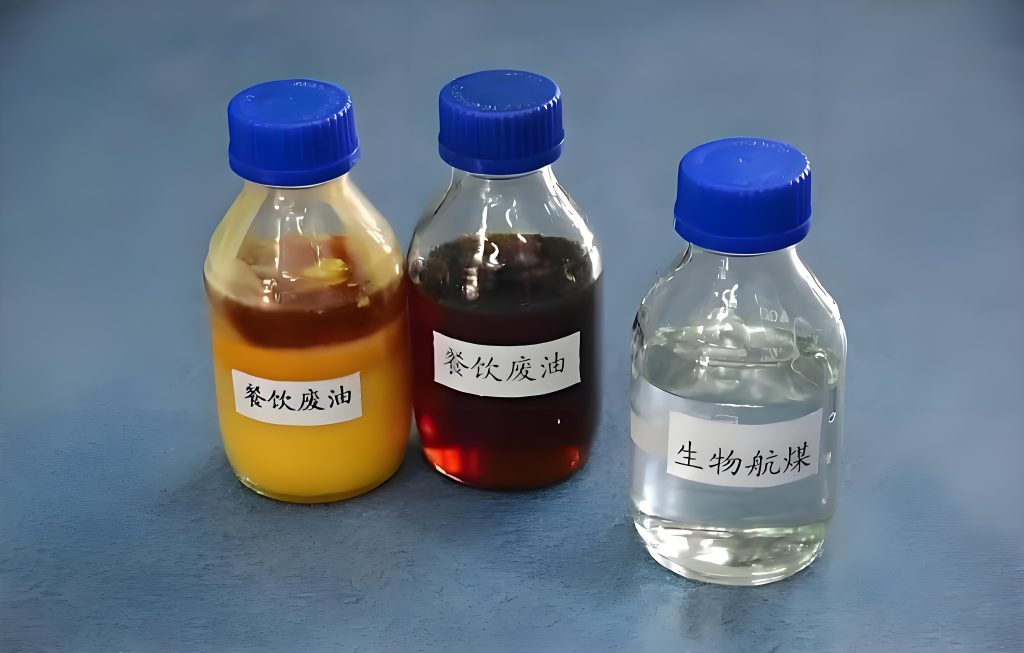

If kerosene contains aromatic components, which makes the oil darker and has a strong smell, how should it be handled?

Method 2: Adsorption separation method

Introduction: Adsorption separation mainly relies on adsorbents to achieve adsorption and separation of target components under the action of mobile phase. There are mainly silica gel, activated alumina, molecular sieves and new adsorbents.

Features: 1. Different adsorbents can be selected according to different oil products.

- Molecular sieves are the most widely used, especially 13X, but they are not suitable for small refineries and small batch processing. One is that the technical parameters are high and the regeneration time is long, resulting in high cost of use and high technical requirements.

- Silica gel has good adsorption and filtration effects. In addition, silica gel has its unique advantages in the decolorization and adsorption of fuel oil-diesel, gasoline, and kerosene. At the same time, it can also reduce the content of sulfur and acid and improve the quality of oil.

There is also a method of solvent extraction, which will be shared next time. #kerosene#aromatics#petroleum#refining#petroleum industry#sulfonation#petroleum purification#petroleum refinery#petroleumbleaching