The waste tires are called black pollution, are difficult to degrade, difficult to recycle.

Our waste tire catalyst is made with special materials by adding precious metals. The catalyst with reasonable pore distribution, suitable surface area and structural stability under hydrothermal conditions, So it can cracks the large molecular characteristics of the tire oil, greatly improves the taste of the oil, and has good stripping performance and regenerative scorch performance, and at the same time limits the deposition of the coke precursor in the pores of the molecular sieve. The reaction cycle is extended and can be used in refineries without hydrogen source.

The diesel oil is light yellow with density 0.85-0.86, and the odor is basically eliminated (due to its cracking treatment on rubber macromolecules). The cetane number is high, the C2 dry gas in the cracking gas is very small, and the liquid yield is above 80%. It also has a pour point depressing effect (the freezing point can be controlled at 0–20 ° C). The catalyst has a long service life. One ton of catalyst can process about 800 tons of tire oil, can be regenerated 2-3 times, and the cost increases from about ¥50/ton to ¥100/ton, eliminating the cumbersome acid-base washing process. The price of oil produced without using catalyst can be 500-1000 yuan higher each ton.

The item number KSC-6A, KSC-6B

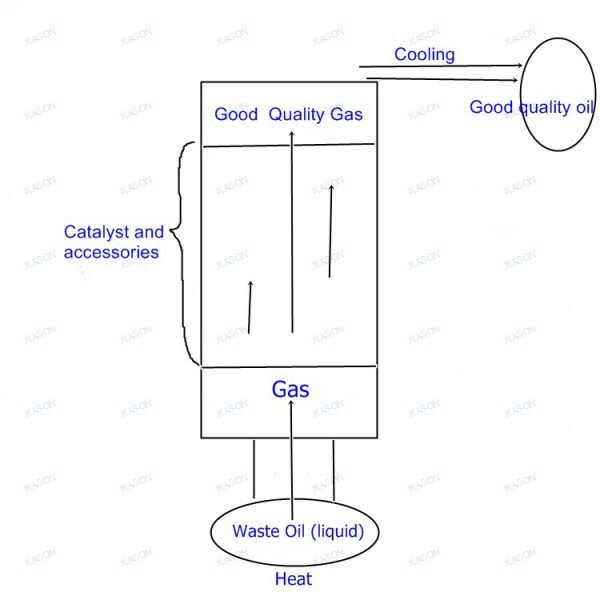

Above is the picture about how the catalyst refinery the waste tire oil to diesel oil

| Item | 6A | 6B | ||

| Standard | Test Result | Standard | Test Result | |

| Size mm | Φ4*2-10 | Φ4*5 | Φ3*2-10 | Φ3*4 |

| Pore Volume ml/g | ≧0.31 | 0.39 | ≧0.31 | 0.36 |

| Specific Surface Area m2/g | ≧240 | 260 | ≧240 | 251 |

| Crushing Strength N/cm | ≧100 | 121 | ≧100 | 117 |

| Bulk Density kg/l | ≧0.8 | 0.88 | ≧0.8 | 0.83 |

| Abrasion wt% | ≦1 | 0.6 | ≦1 | 0.5 |

Catalyst packing should be with bag or barrel packing.

Bag packing with 25kg/bag, barrel packing with 40kg/barrel.

Bag packing with 15-18 tons in 1*20GP, barrel packing with 14-15 tons in 1*20GP.

Contact Form